Understanding Wheel Bearing Failure Signs Sounds and Solutions

Sharing this:

Have you ever heard a strange humming or grinding noise while driving that seems to get louder as you accelerate? That mysterious sound might be more than just an annoyance; it could be a warning sign of failing wheel bearings.

Wheel bearings are critical components that allow your wheels to spin freely while supporting the weight of your vehicle. When they begin to fail, they don't just create annoying sounds; they compromise your vehicle's safety and handling. At Blue Ridge Automotive, we see vehicles with wheel bearing issues every day.

In this comprehensive guide, we'll explore wheel bearing failure symptoms, decode the various sounds they make, and outline practical solutions to address these issues before they escalate into major repairs. Let's dive into everything you need to know about wheel bearing health and maintenance.

Discover How Wheel Bearings Keep You Safe on the Road

Wheel bearings are precision-engineered steel balls or rollers housed in a metal ring called a race. They're designed to reduce friction between the wheel hub and the axle, allowing your wheels to rotate smoothly while supporting the weight of your vehicle.

These seemingly simple components perform a complex and vital function in your vehicle's operation. Each wheel on your vehicle has its wheel bearing assembly. These bearings are packed with grease and sealed to keep contaminants out and lubricant in.

Modern wheel bearings are typically sealed units that aren't serviceable and must be replaced when they fail. However, some older vehicles may have bearings that can be repacked with grease during maintenance.

The importance of wheel bearings cannot be overstated. They not only enable smooth wheel rotation but also:

- Support the vehicle's weight while distributing loads evenly

- Allow minimal friction between moving parts, improving fuel efficiency

- Help maintain proper tire contact with the road for optimal handling

When wheel bearings begin to fail, your vehicle's safety and performance are directly affected. Excessive play in the bearings can lead to irregular tire wear, poor handling, and in extreme cases, complete wheel detachment, a catastrophic failure you certainly want to avoid. That's why understanding the signs of wheel bearing failure is crucial for every vehicle owner.

Catch These Early Signs Before Wheel Bearings Fail

Detecting wheel bearing problems early can save you from more extensive damage and costly repairs. Here are the key warning signs to watch for:

Unusual Noises

The most common symptom of a failing wheel bearing is noise. As bearings wear down, they produce the following distinctive sounds that often change with vehicle speed or when turning:

- Humming or Droning: A constant, low-pitched humming noise that increases with speed often indicates bearing wear.

- Growling or Rumbling: These deeper sounds typically occur when the bearing has significant damage.

- Clicking or Popping: These noises, especially during turns, suggest advanced bearing deterioration.

- Grinding: A harsh grinding sound usually means the bearing has little to no lubricant left, and metal-on-metal contact is occurring.

These noises may be more noticeable when accelerating, decelerating, or making turns. Many drivers report that the sound changes when turning in one direction versus the other, and this can help pinpoint which wheel bearing is failing.

Steering and Handling Issues

Failing wheel bearings don't just make noise; they affect how your vehicle handles. Look out for:

- Steering wheel vibration that increases with speed

- The vehicle is pulling to one side during normal driving

- Loose or "wandering" steering feel

- Increased steering effort, especially during turns

These wheel bearing failure symptoms can sometimes be confused with alignment or tire issues, but when combined with unusual noises, they strongly suggest wheel bearing problems. At Blue Ridge Automotive, our technicians can perform a thorough inspection to determine exactly what's causing these symptoms.

Visible Wear and Physical Symptoms

In addition to sounds and handling changes, physical signs can indicate wheel bearing issues:

- Uneven tire wear, particularly on the inner or outer edges

- Excessive heat around the wheel hub (which you might notice when washing your car)

- Visible play or movement in the wheel when jacked up and checked

- ABS warning light illumination (modern wheel bearings often house ABS sensors)

If you notice any of these symptoms, it's important to have your vehicle inspected promptly. Wheel bearing problems typically worsen over time, and addressing them early can prevent more serious damage to related components.

DIY Ways to Check for Wheel Bearing Trouble

While professional diagnosis is always recommended for wheel bearing issues, there are a few checks you can perform yourself to help determine if your suspicions are correct.

The first and simplest check is the "road test" method. Find a safe, straight road with minimal traffic and drive at a moderate speed (around 40 mph). Gently shift your vehicle's weight from side to side by slightly turning the steering wheel. If a wheel bearing is failing, the noise will often increase when you put weight on the affected side.

For a more hands-on approach, you can perform a basic wheel check if you have the tools and knowledge to safely jack up your vehicle:

- Properly secure your vehicle on jack stands (never rely solely on a jack)

- Grip the tire at the 12 and 6 o'clock positions and try to rock it

- Then grip at the 3 and 9 o'clock positions and repeat

Any noticeable movement or play could indicate a failing wheel bearing. However, some movement is normal in vehicles with certain suspension designs, so it's important to compare both sides of the vehicle.

Remember that wheel bearings aren't the only components that can cause similar symptoms. Worn suspension parts, damaged CV joints, or tire issues can produce comparable noises and handling problems.

That's why professional diagnosis from a trusted shop like Blue Ridge Automotive is invaluable; our experienced technicians can distinguish between these various issues and provide an accurate assessment.

Decode Wheel Bearing Noises and Their Severity

The sounds produced by failing wheel bearings can tell you a lot about the severity of the problem. Learning to interpret these noises can help you decide how urgently you need to address the issue.

Types of Wheel Bearing Noises

Different sounds typically correspond to different stages of bearing wear:

Early Stage Failure

- A subtle humming or drone that's most noticeable at highway speeds

- Noise that increases or decreases proportionally with vehicle speed

- Sound may disappear at certain speeds and reappear at others

Moderate Failure

- More pronounced growling or rumbling that's audible

- Noise that changes when turning or shifting weight in the vehicle

- Sound that worsens when cornering in one direction (typically louder when turning toward the affected side)

Advanced Failure

- Loud grinding or scraping that's impossible to ignore

- Constant noise regardless of speed or direction

- May be accompanied by vibration felt through the floor or steering wheel

The location of the noise can also help identify which bearing is failing. Front wheel bearing noise is often more noticeable when turning, while rear wheel bearing noise tends to be more constant. Noise from driver-side bearings is typically more audible to the driver, while passenger-side bearing noise might seem more distant.

It's important to note that wheel bearing noises can sometimes be confused with other issues. For example, tire noise from uneven wear patterns can mimic bearing sounds, and certain brake problems can produce similar grinding noises. This is why professional diagnosis from the skilled technicians at our brake services department can be invaluable in pinpointing the exact cause.

Know When It’s Time to Replace Wheel Bearings

Knowing when to replace wheel bearings is crucial for maintaining vehicle safety and preventing cascading damage to other components. Here's what you need to know about timing and necessity:

When Replacement Is Necessary

Unlike some vehicle components that can be serviced or repaired, modern wheel bearings are typically sealed units that must be replaced entirely when they fail. Here are some scenarios that necessitate replacement:

- When bearing noise becomes noticeable and consistent

- If there's any detectable play in the wheel when checked

- After significant water exposure (such as deep flooding)

- Following certain accidents or impacts that could damage the bearings

- As a preventive measure, when replacing other related components

- When an ABS sensor integrated with the bearing assembly fails

Typically, wheel bearings are designed to last 85,000-100,000 miles under normal driving conditions. However, factors like rough roads, frequent puddles or water crossings, and heavy loads can significantly reduce their lifespan.

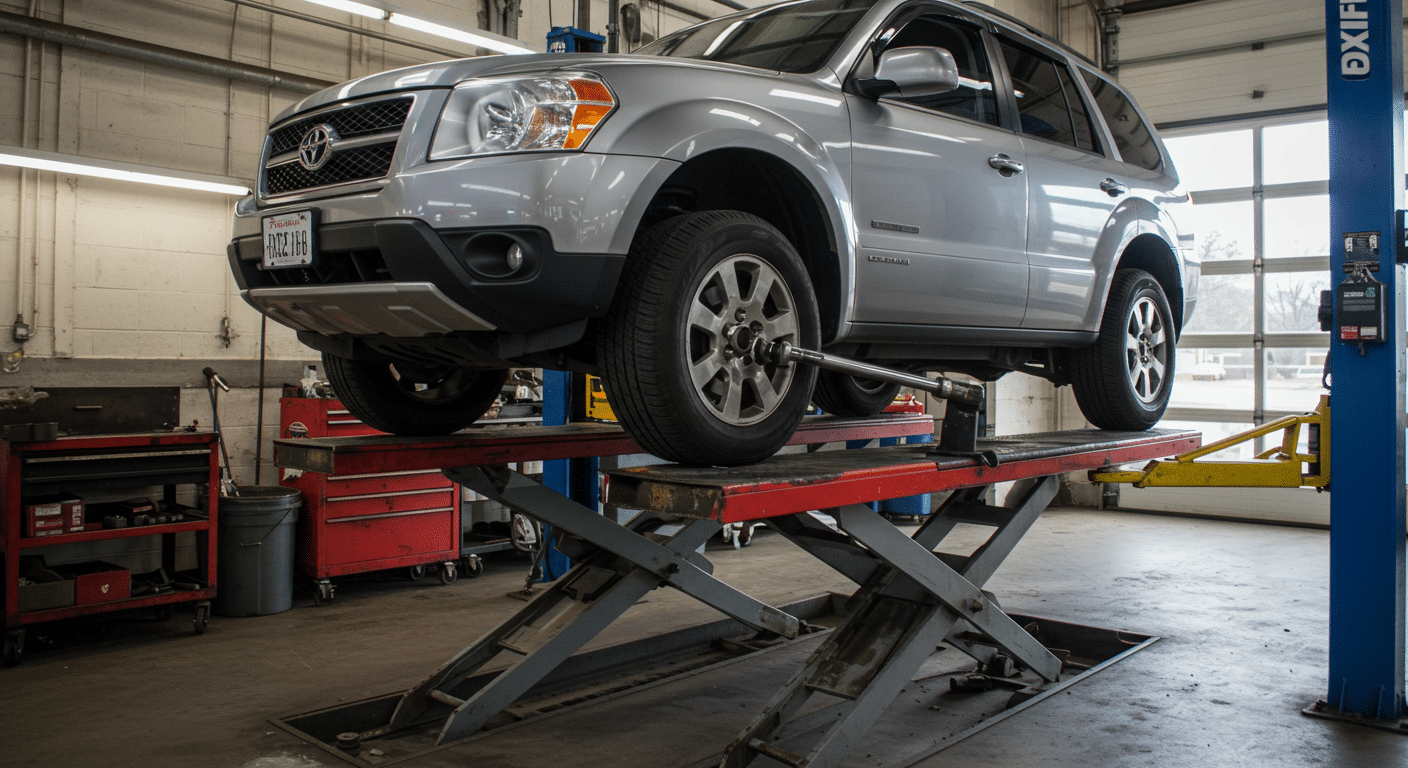

The Replacement Process

Wheel bearing replacement is not typically a DIY job for most vehicle owners. The process requires specialized tools, precise torque specifications, and technical knowledge. Here's a simplified overview of what the replacement process involves:

- The vehicle is lifted and secured on a lift or jack stands

- Wheel and brake components are removed for access

- The hub assembly is detached (methods vary by vehicle design)

- The old bearing is pressed out, or the entire hub/bearing assembly is replaced

- New components are installed following the manufacturer's specifications

- Proper torque is applied to all fasteners

- The system is reassembled and tested

Many modern vehicles use hub assemblies that include the wheel bearing, hub, and sometimes the ABS sensor in a single unit. These "hub bearing assemblies" simplify the replacement process but can be more expensive than traditional bearings.

At Blue Ridge Automotive, our certified technicians have the tools and expertise to properly diagnose and replace wheel bearings on virtually any make and model. We ensure that all specifications are followed precisely, which is critical for bearing longevity and proper vehicle handling.

Pro Tips to Extend the Life of Your Wheel Bearings

While wheel bearings eventually wear out regardless of maintenance, their lifespan can be significantly extended through proper care and driving habits. Here are effective strategies to help prevent premature wheel bearing failure:

Driving Habits That Protect Your Bearings

How you drive and where you drive can have a substantial impact on wheel bearing life:

- Avoid hitting potholes and curbs when possible

- Reduce speed when driving on rough or uneven roads

- Avoid driving through deep water or puddles when you can

- Don't overload your vehicle beyond the manufacturer's specifications

- Use caution when towing to avoid excess strain on bearings

Maintenance Practices

Regular maintenance can help identify potential bearing issues before they become serious problems:

- Have your suspension checked regularly as part of routine maintenance

- Pay attention to tire wear patterns that might indicate bearing issues

- Address any unusual noises promptly

- Ensure proper wheel alignment and tire balance

On older vehicles with serviceable bearings, periodic repacking with fresh grease can extend bearing life. However, most modern vehicles use sealed bearings that cannot be serviced this way.

It's also worth noting that wheel bearings work in concert with other suspension components. Worn shocks and struts can place additional stress on wheel bearings, leading to premature failure. Maintaining your entire suspension system helps protect your bearings and other components.

Why Ignoring Wheel Bearing Issues Can Cost You More

Delaying wheel bearing replacement when problems arise can lead to significant consequences, both financially and safety-wise. Here's what can happen if wheel bearing issues are left unaddressed:

Safety Implications

Failing wheel bearings create the following serious safety hazards:

- Reduced vehicle control and unpredictable handling

- Compromised braking performance

- Risk of wheel seizure at high speeds

- In extreme cases, complete wheel detachment

These safety risks increase dramatically as bearing deterioration progresses. What starts as an annoying noise can quickly evolve into a dangerous driving condition.

Cascading Damage

When wheel bearings fail, they rarely fail alone. Expect these issues with wheel bearing failure:

- Damage to the wheel hub and spindle

- ABS sensor failure

- CV joint damage

- Potential damage to brake components

- Accelerated and uneven tire wear

The cost of repairing this cascade of damage is typically much higher than addressing the bearing issue early. What might start as a $300-500 repair can easily balloon into repairs costing $1,000 or more when additional components become damaged.

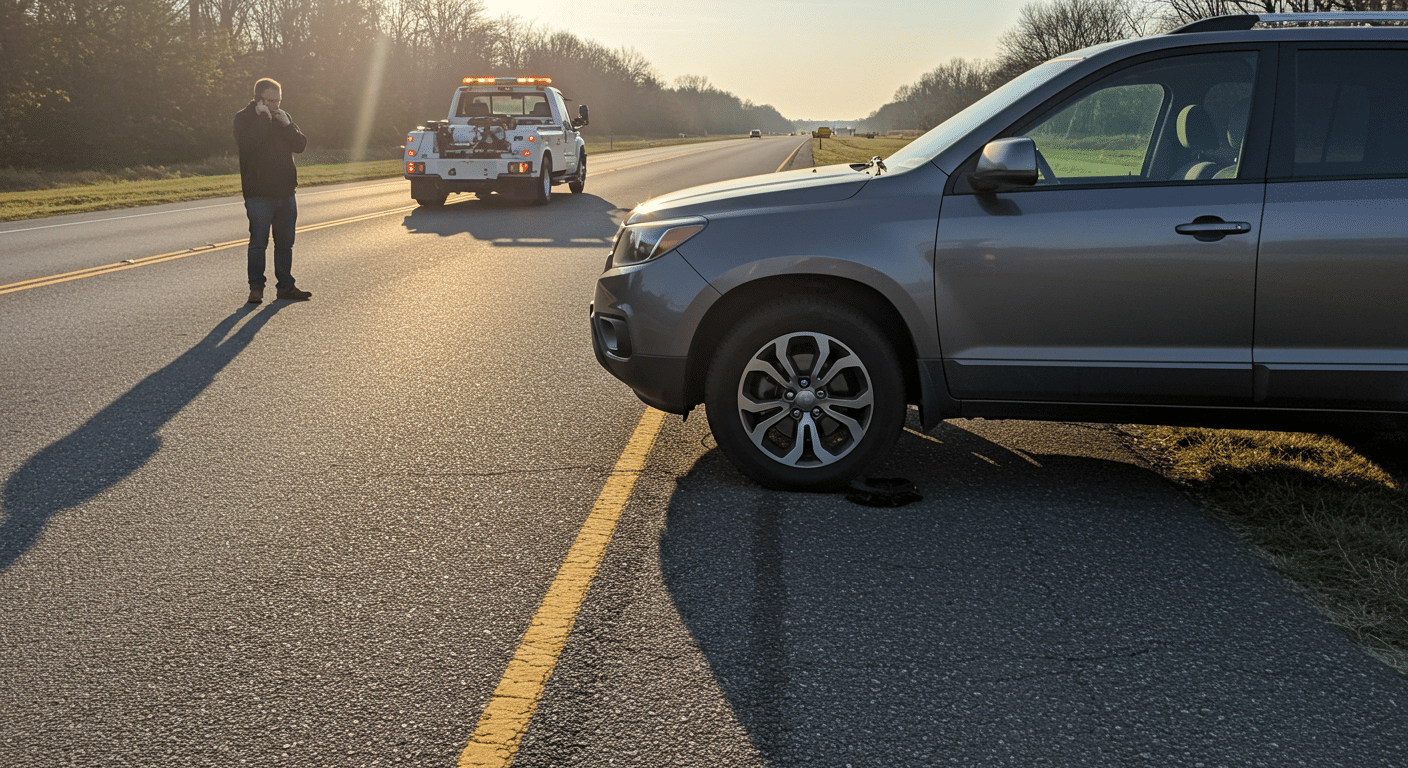

Additionally, catastrophic bearing failure often leaves drivers stranded, necessitating a tow and creating inconvenience beyond just the repair costs. For busy professionals or families, this unexpected downtime can be particularly problematic.

At Blue Ridge Automotive, we've seen countless examples of minor bearing issues that evolved into major repairs because they were ignored. Our approach focuses on identifying these problems early during routine maintenance, potentially saving our clients significant money and hassle.

Frequently Asked Questions

How long can I drive with a bad wheel bearing?

While you might be able to drive for hundreds or even thousands of miles with early signs of wheel bearing wear, it's not recommended to drive any longer than necessary once you notice symptoms. A completely failed bearing can lock up without warning, causing you to lose control of your vehicle.

As soon as you identify wheel bearing noise or other symptoms, schedule a repair as soon as possible. Safety should always be your priority when dealing with critical components like wheel bearings.

Will a bad wheel bearing affect braking performance?

Yes, a failing wheel bearing can impact your braking performance. As the bearing deteriorates, it creates excessive play in the wheel assembly, which can cause uneven braking and increased stopping distances.

In vehicles with ABS, the wheel speed sensors are often integrated with the bearing assembly, so bearing failure can trigger ABS malfunctions or warning lights. Additionally, the heat generated by a failing bearing can potentially damage nearby brake components, further compromising your vehicle's stopping ability.

Can wheel bearings fail suddenly without warning?

While sudden, catastrophic wheel bearing failure without prior warning is rare, it can happen. Most wheel bearings deteriorate gradually, providing symptoms like noise and vibration for weeks or months before complete failure. However, severe impacts (like hitting a large pothole at high speed) can cause immediate damage that leads to rapid failure.

Water contamination from driving through deep puddles or floods can also wash away bearing lubricant, causing accelerated wear and potentially sudden failure. Regular vehicle inspections can help catch bearing issues before they reach this point.

Do I need to replace wheel bearings in pairs?

Unlike some components like struts or brake pads, wheel bearings don't necessarily need to be replaced in pairs. Each bearing wears independently based on road conditions, driving habits, and manufacturing variations.

However, if both front and rear bearings have similar mileage and one has failed, it's often wise to consider replacing both as a preventive maintenance measure. This approach can save you time and labor costs, as much of the expense in bearing replacement is in the labor rather than the parts themselves.

What's the average cost to replace wheel bearings?

Wheel bearing replacement costs vary significantly depending on your vehicle make and model, the type of bearing assembly, and your geographic location. On average, you can expect to pay between $250 and $500 per wheel for bearing replacement, including parts and labor.

Some luxury or specialized vehicles may cost more, sometimes exceeding $700 per wheel. Front wheel bearings often cost more to replace than rear ones due to their more complex design in many vehicles. Getting multiple quotes from reputable shops like ours can help ensure you're getting a fair price for quality work.

Contact Blue Ridge Automotive for Reliable Wheel Bearing Repair

Wheel bearings may be small components, but they play a massive role in your vehicle's safety and performance. Understanding the signs and sounds of wheel bearing failure empowers you to address issues before they escalate into dangerous and expensive problems.

From the distinctive humming and grinding noises to handling changes and physical symptoms, recognizing these warning signs early can save you significant money and prevent potential safety hazards on the road.

Remember that proper maintenance and careful driving habits can extend bearing life, but all bearings eventually require replacement. When that time comes, connect with Blue Ridge Automotive for trusted wheel bearing diagnostics and replacement services tailored to your specific vehicle.

About Blue Ridge Automotive

We provide trusted automotive care with a focus on safety, performance, and long-term value. Our team of certified technicians delivers reliable repair services, with deep experience in diagnosing and resolving wheel bearing issues across a wide range of vehicles.

Blue Ridge Automotive is committed to keeping your vehicle running smoothly with precision maintenance and repairs backed by years of hands-on experience. Contact us today to book an appointment or learn more about our services.