When that telltale squealing or grinding sound starts coming from your wheels, you know it's time to address your vehicle's braking system. Brake maintenance isn't just about preserving your car's performance; it's critical for your safety on the road. But for many drivers, the uncertainty around brake replacement costs can lead to procrastination or overpaying.

The cost to replace brake pads and rotors can vary significantly based on several factors, including vehicle type, parts quality, and where you get the service performed. At Blue Ridge Automotive, we've seen firsthand how understanding these variables can help drivers budget appropriately and avoid unnecessary expenses.

In this comprehensive guide, we'll break down everything you need to know about brake replacement costs, help you identify when replacement is necessary, and provide tips for getting the best value without compromising your safety.

Know What You're Paying For: Key Brake Components Explained

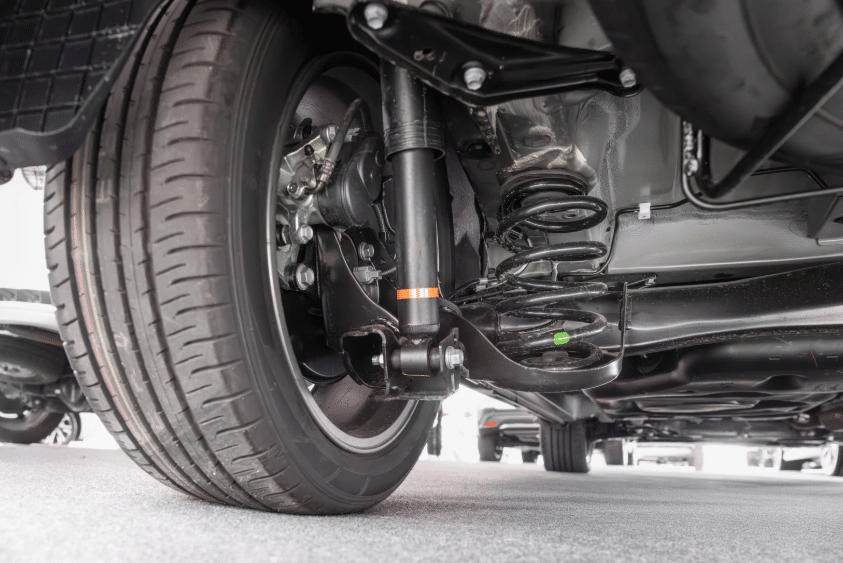

Before diving into costs, it's important to understand what you're paying for. Your vehicle's braking system consists of several crucial components that work together to stop your car safely.

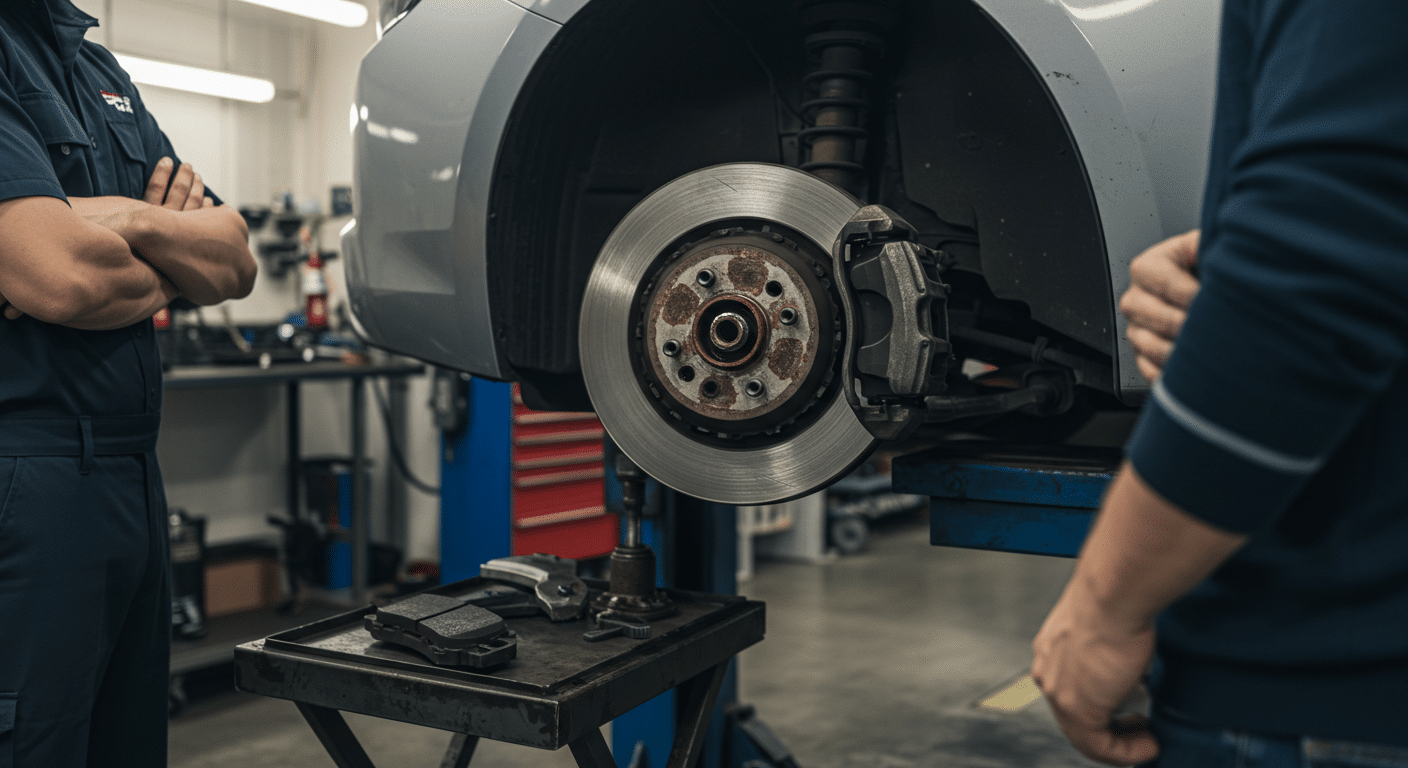

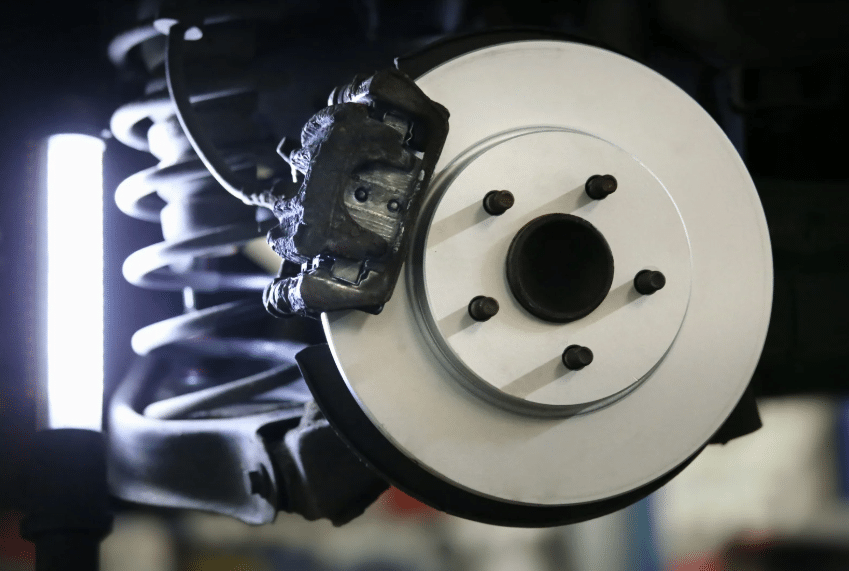

Brake pads are the friction material that presses against the rotors to slow your vehicle. Made of composite materials designed to withstand heat and pressure, these components naturally wear down over time. Most vehicles use different types of brake pads. Whether semi-metallic, ceramic, or organic, each pad has varying price points and performance characteristics.

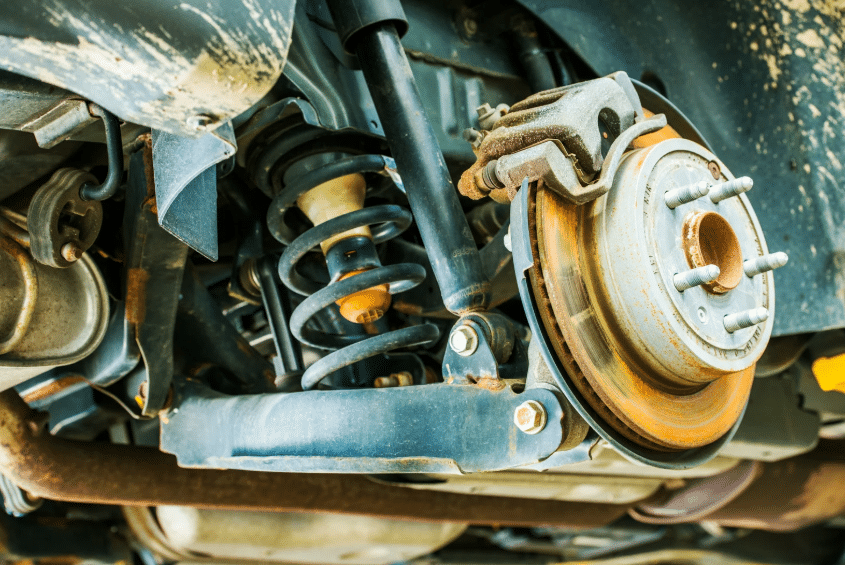

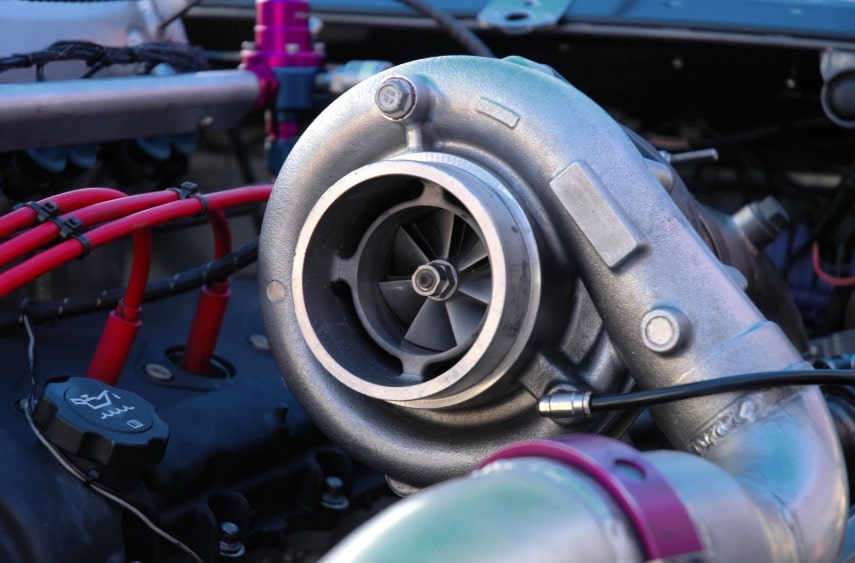

Rotors (also called brake discs) are the metal discs attached to your wheels that the brake pads clamp onto when you press the brake pedal. These can become warped or worn over time, reducing braking efficiency and safety. Unlike pads, rotors are typically made of cast iron or carbon-ceramic material for high-performance vehicles.

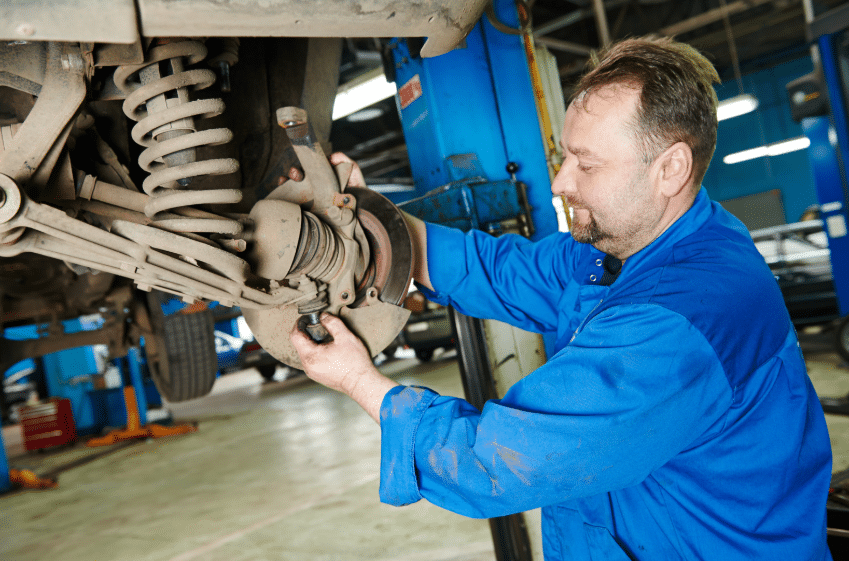

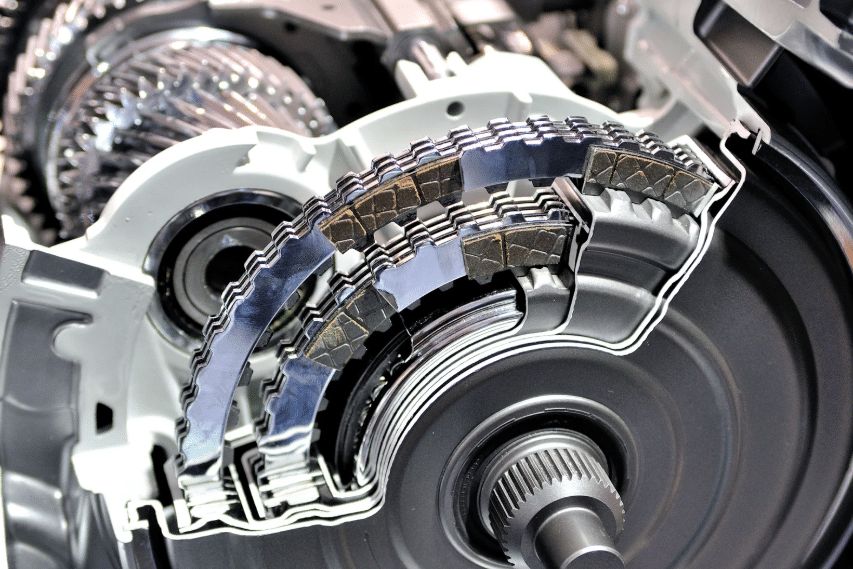

Calipers are the components that house the brake pads and push them against the rotors when you press the brake pedal. While calipers generally last longer than pads and rotors, they can occasionally need replacement or rebuilding.

According to industry data from 2024, most drivers replace their brake pads every 30,000 to 70,000 miles, while rotors typically last for 50,000 to 70,000 miles, depending on driving habits and conditions. At Blue Ridge Automotive, our technicians can perform a comprehensive brake inspection to determine exactly which components need attention.

Plan Your Budget: What Brake Pad and Rotor Replacement Really Costs

The cost of replacing brake pads and rotors can vary widely depending on several factors, but understanding average price ranges can help you budget appropriately.

For standard brake pad replacement alone, most drivers can expect to pay between $250 and $350 per axle. This typically includes the parts and labor for replacing just the brake pads on either the front or rear wheels.

When replacing both brake pads and rotors, the cost increases significantly. On average, expect to pay between $500 and $800 per axle for parts and labor. This higher price reflects the additional cost of the rotors themselves and the extra labor required.

Here's a more detailed breakdown of what contributes to these costs:

- Part Costs: Brake pads range from $75 to $125 per set, depending on quality, while rotors typically cost between $75 and $175 each.

- Labor Costs: Professional installation typically runs between $125 and $175 per hour, with a complete brake job taking 1-3 hours, depending on the vehicle.

Premium or performance vehicles like Mercedes, BMW, or Audi will typically fall at the higher end of these ranges or even exceed them, with some luxury brake jobs costing $1,000 or more per axle.

Understand What Drives Brake Service Pricing

Several key factors can significantly impact how much you'll pay for brake service:

Vehicle Make and Model

The type of vehicle you drive is perhaps the biggest cost determinant. Economy cars typically have the most affordable brake components, while luxury and performance vehicles require specialized, more expensive parts. For example, replacing brake pads and rotors on a Honda Civic might cost $450-600 for the front axle, while the same service on a BMW 5-series could easily exceed $800.

Truck and SUV owners should also expect higher costs due to the larger, heavier-duty components required for these vehicles. These larger vehicles put more strain on braking systems, requiring more robust parts that come with higher price tags.

Quality of Replacement Parts

Brake components come in various quality levels, from economy to premium and performance grades:

- Economy/standard parts typically cost 30-50% less than premium options, but may wear out faster

- OEM (Original Equipment Manufacturer) parts match what came with your vehicle from the factory

- Premium aftermarket parts often offer improved performance or longevity

- Performance or specialty parts designed for specific conditions can cost significantly more

According to a 2024 industry survey, premium brake pads last approximately 25% longer than economy options, potentially offering better value despite the higher initial cost.

Service Location

Where you get your brake work done significantly impacts your total cost:

- Dealerships typically charge the highest rates, often 20-40% more than independent shops

- Independent repair shops usually offer more competitive pricing with comparable quality

- Chain repair facilities may offer promotions, but sometimes use lower-quality parts

- DIY replacement saves on labor but requires tools and expertise

At Blue Ridge Automotive, we provide competitive pricing while using high-quality parts and employing ASE-certified technicians who specialize in brake systems.

Spot the Warning Signs Before Brake Problems Worsen

Knowing when to replace your brakes can save you money and prevent dangerous failures. Here are the telltale signs that your braking system needs attention:

Audible Warning Signs

That high-pitched squealing when you apply the brakes isn't just annoying, it's a deliberate design feature. Most brake pads include wear indicators that create a squealing noise when the pad material has worn down to a certain level.

If ignored, this squealing eventually transitions to a harsh grinding sound, indicating metal-on-metal contact that's damaging your rotors. Other concerning sounds include clicking, rattling, or vibrating noises when braking, which could indicate loose components or unevenly worn pads and rotors.

Physical and Performance Indicators

Beyond sound, your vehicle provides several other indicators of brake system issues:

- Vibration or pulsation in the brake pedal often indicates warped rotors

- Longer stopping distances suggest reduced braking efficiency

- A brake pedal that feels "soft" or sinks to the floor may indicate hydraulic problems

- Pulling to one side during braking suggests uneven wear or a stuck caliper

- Visual inspection shows less than 1/4 inch of pad material remaining

According to the National Highway Traffic Safety Administration (NHTSA), brake-related problems contribute to approximately 22% of vehicle crashes caused by mechanical failure. Regular inspection and timely replacement are crucial safety measures.

For a professional brake inspection to identify potential issues before they become safety hazards, our certified technicians can provide a comprehensive evaluation.

Choose the Right Approach Between DIY vs. Pro Brake Replacement

Many car enthusiasts consider brake replacement a manageable DIY project, while others prefer leaving it to professionals. Each approach has distinct advantages and considerations.

DIY Brake Replacement

Taking the DIY approach can save you $150-300 in labor costs per axle. However, you'll need:

- Basic mechanical tools including jack stands, lug wrench, C-clamp, and socket set

- A safe workspace with solid, level ground

- Technical knowledge or the ability to follow detailed instructions

- 2-4 hours per axle for first-timers

The potential savings are significant, but the learning curve can be steep. A 2024 survey of DIY mechanics found that first-time brake jobs took an average of 3.5 hours per axle, compared to 1 hour for professionals.

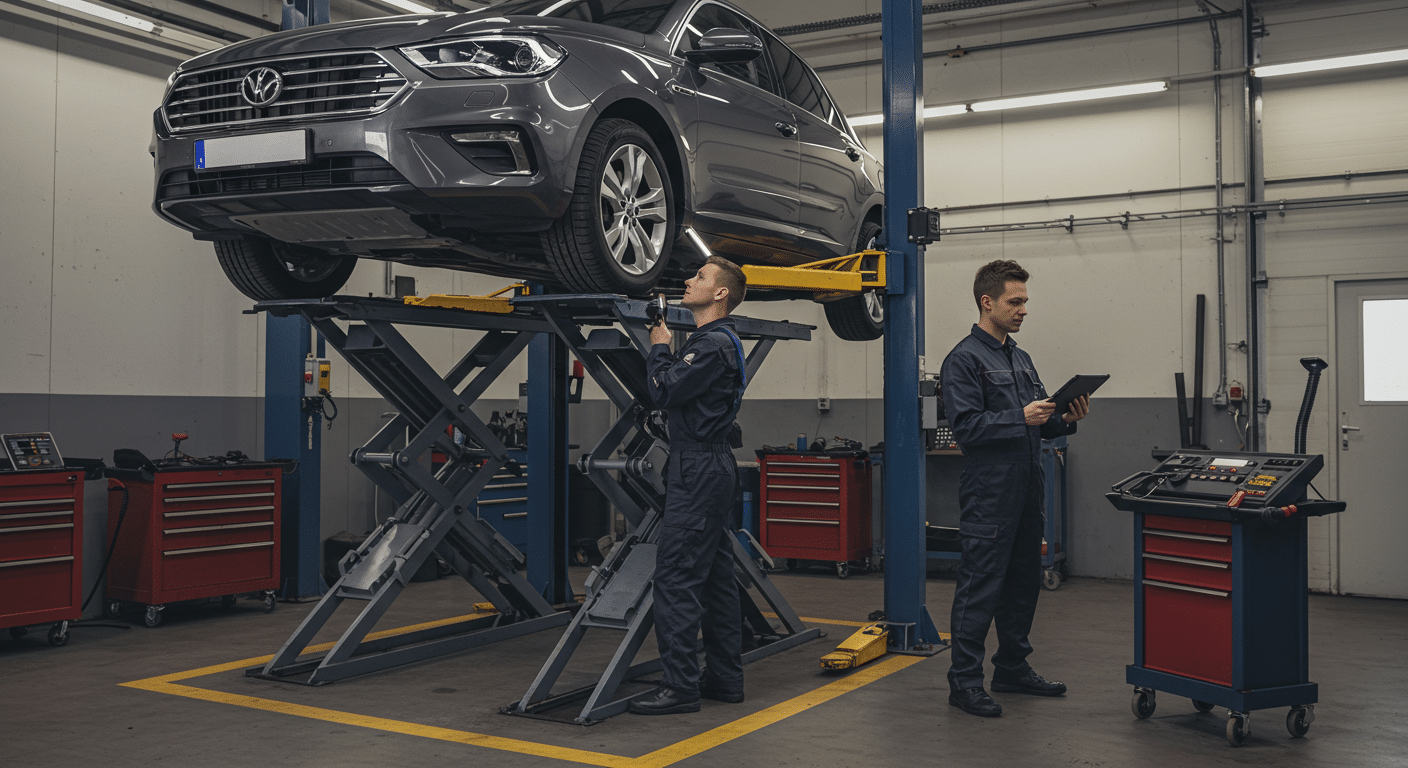

Professional Brake Service Benefits

Having your brakes professionally replaced offers several advantages:

- Technician expertise and specialized tools ensure proper installation

- Additional inspection of related components that might need attention

- Labor warranties (typically 12-24 months) protect against installation issues

- Professional shops can properly dispose of old parts and hazardous materials

- Most shops can complete the job in 1-2 hours per axle

"We had a customer who attempted a DIY brake job and accidentally damaged an ABS sensor, turning a $500 brake job into a $900 repair," shares a service manager at Blue Ridge Automotive. "While DIY is tempting, safety-critical systems sometimes warrant professional attention."

Smart Ways to Cut Brake Replacement Costs Without Risking Safety

While brake replacement is a necessary expense, there are legitimate ways to reduce costs without compromising safety:

Compare Quotes and Options

Don't settle for the first estimate you receive. Getting quotes from 3-4 reputable shops can reveal significant price differences for the same service. When comparing, make sure you understand:

- What quality level of parts are they using

- Whether they're replacing both pads and rotors or just pads

- If the price includes additional services like caliper rebuilding or brake fluid flush

- What warranty is offered on parts and labor

Consider Partial Replacement When Appropriate

In some cases, you may not need to replace everything:

- Brake pads wear out faster than rotors; sometimes you can replace just the pads

- Front brakes typically wear 2-3 times faster than rear brakes due to weight distribution

- Some rotors can be "turned" (resurfaced) rather than replaced if they have adequate thickness

However, if rotors show signs of heat damage, cracks, or excessive wear, replacement is the safer option. A professional inspection can determine whether partial replacement is appropriate for your vehicle.

Timing and Maintenance Considerations

Regular maintenance can extend the life of your braking system:

- Address squealing or performance issues promptly before they cause rotor damage

- Consider brake service during other major maintenance for potential labor savings

- Follow manufacturer-recommended brake fluid replacement (typically every 2-3 years)

- Adjust driving habits to reduce brake wear (avoiding "riding" the brakes, harsh stops)

According to a 2024 maintenance study, drivers who respond promptly to the first signs of brake wear spent an average of 30% less on brake maintenance over their vehicle's lifetime compared to those who delayed service.

For comprehensive brake services that include thorough inspection and maintenance recommendations, our experts can help extend the life of your braking system while keeping you safe.

Get More from Your Brake Service with the Right Warranty

Not all brake jobs are created equal, and understanding warranty coverage can help you determine the true value of the service you're receiving.

Most quality brake components come with a manufacturer's warranty covering defects for a specific period, typically 12 to 36 months. However, these warranties usually cover only the parts themselves, not labor for replacement.

Shop-provided labor warranties vary widely, from as little as 90 days to "lifetime" coverage. When comparing quotes, consider the total warranty package. A slightly higher initial cost might provide significantly better warranty coverage, ultimately delivering better value.

When evaluating brake service providers, ask these specific warranty questions:

- What's covered under the parts warranty: just defects, or also normal wear?

- How long is the labor warranty if problems arise from installation?

- Are there mileage limitations on the warranty?

- What documentation is needed if warranty service is required?

Remember that proper maintenance also affects warranty coverage. Most warranties require reasonable care and maintenance of your vehicle to remain valid.

Frequently Asked Questions

How often do brake pads and rotors need to be replaced?

Brake pads typically need replacement every 30,000 to 70,000 miles, depending on your driving habits, vehicle type, and brake pad quality. Aggressive driving in stop-and-go traffic will wear pads faster than highway cruising.

Rotors generally last longer, often 50,000 to 70,000 miles, but can sometimes need replacement along with pads if they've become too thin, warped, or damaged. Regular inspections during oil changes can help catch wear before it becomes a safety issue.

Can I replace just the brake pads without replacing the rotors?

Yes, in many cases, you can replace just the brake pads if your rotors are still in good condition with adequate thickness remaining. However, if rotors show signs of scoring, grooving, or have excessive runout (wobble), they should be replaced simultaneously.

Some mechanics recommend at least resurfacing rotors when installing new pads to ensure proper contact and performance. This decision should be based on rotor measurements and visual inspection by a qualified technician.

What's the difference between economy and premium brake components?

Economy brake components typically use less expensive materials that may wear faster or provide less optimal braking performance. Premium brake components often feature higher-quality friction materials, better heat dissipation, and more precise manufacturing tolerances.

Premium pads might include features like chamfered edges to reduce noise and shims to prevent vibration. While premium components cost more initially, they often provide better value through longer service life, improved stopping power, and quieter operation, especially important for heavier vehicles or those used for towing.

How long does a brake replacement service take?

A professional brake replacement typically takes 1-2 hours per axle (front or rear) when performed by experienced technicians with proper equipment. This includes removing wheels, replacing components, and testing.

DIY replacements usually take considerably longer, about 2-4 hours per axle for someone with moderate mechanical experience, and potentially longer for first-timers. Complete brake jobs involving all four wheels, fluid flush, and other related services might require 3-5 hours total at a professional shop.

Will my car insurance cover brake replacement?

Standard auto insurance policies do not cover maintenance items like brake replacement, as these are considered expected wear components. Insurance only covers brake damage resulting from a covered accident.

Extended warranties or vehicle service contracts might cover brake components if failure occurs due to defects rather than normal wear, but most exclude wear items like brake pads. It's best to budget for brake maintenance as a regular ownership expense, similar to tires or oil changes.

Stay Safe and Informed with Smart Brake Maintenance Decisions

Replacing brake pads and rotors represents a significant but necessary investment in your vehicle's safety and performance. While costs typically range from $300-700 per axle for parts and labor, understanding the factors that influence pricing empowers you to make informed decisions.

By recognizing the signs of brake wear early, comparing service options carefully, and considering the total value, including warranty coverage, you can manage costs effectively without compromising safety. Remember that brakes are perhaps your vehicle's most critical safety system.

Investing in quality components and professional installation provides safety that far outweighs the potential savings of cutting corners. If you're experiencing any brake issues or approaching the typical replacement interval, contact a reputable service provider for an inspection and detailed estimate tailored to your specific vehicle.

About Blue Ridge Automotive

Blue Ridge Automotive offers full-service auto repair and maintenance, backed by over 25 years of experience in the Atlanta area. Our ASE-certified technicians specialize in brake system diagnostics, repairs, and replacements for all makes and models. Services include pad and rotor replacement, caliper repair, brake fluid service, and ABS diagnostics.

We stay current on braking technologies, from traditional systems to those in hybrid and electric vehicles, through ongoing technician training. Our shop uses OEM or premium aftermarket parts and backs all work with strong warranties. With advanced diagnostic tools, we catch brake issues early before they impact your safety.

Contact our team to schedule a full brake inspection and explore service options tailored to your vehicle. We’ve helped thousands of Atlanta drivers stay safe with reliable brake service that fits their needs and budget.

Maintaining your vehicle's transmission is essential for its longevity and performance. While many car owners understand the importance of regular oil changes, transmission fluid often gets overlooked until problems arise. Regular transmission fluid changes can extend your vehicle's life and help avoid costly repairs down the road.

The fluid lubricates, cools, and cleans the transmission components, ensuring smooth gear shifts and optimal performance. At Blue Ridge Automotive, we recommend transmission fluid changes as part of your regular maintenance schedule, but we also understand that some car enthusiasts prefer handling maintenance tasks themselves.

This guide provides step-by-step instructions for both automatic and manual transmission fluid changes, including the tools you'll need, safety precautions, and tips for ensuring the job is done correctly. Whether you're a seasoned DIY mechanic or trying your hand at car maintenance for the first time, these instructions will help you complete the task with confidence.

Protect Your Transmission by Understanding Fluid Function

Transmission fluid serves several critical functions in your vehicle. For automatic transmissions, the fluid acts as a hydraulic medium to transfer power from the engine to the transmission. In manual transmissions, it primarily serves as a lubricant for the gears and synchronizers.

Over time, transmission fluid breaks down and becomes contaminated with metal particles, friction material, and other debris. This degradation can lead to:

- Rough or delayed shifting

- Transmission overheating

- Premature wear of internal components

- Complete transmission failure in severe cases

Different vehicles require specific types of transmission fluid. Using the wrong type can cause serious damage to your transmission. Always consult your owner's manual or a trusted mechanic to determine the correct fluid for your vehicle.

The frequency of transmission fluid changes varies depending on your driving habits, vehicle make, and model. As a general rule, automatic transmission fluid should be changed every 30,000 to 60,000 miles, while manual transmission fluid typically lasts 30,000 to 90,000 miles. However, if you frequently tow heavy loads or drive in severe conditions, more frequent changes may be necessary.

Gather Essential Tools and Materials Before You Start

Before beginning your transmission fluid change, gather all necessary tools and materials. Proper preparation will ensure the job goes smoothly and safely. Here's what you'll need:

For automatic transmissions:

- Transmission fluid (specific to your vehicle)

- Transmission filter kit (if applicable)

- Transmission pan gasket (if changing the filter)

- Drain pan (minimum 5-quart capacity)

- Jack and jack stands or vehicle ramps

- Socket set and wrenches

- Torque wrench

- Funnel

- Shop rags

- Gloves and safety glasses

For manual transmissions:

- Manual transmission fluid (specific to your vehicle)

- Drain pan

- Socket set and wrenches

- Funnel with a flexible hose attachment

- Shop rags

- Gloves and safety glasses

Additionally, you might need a fluid pump for refilling certain transmissions, particularly those without dipsticks or with fill plugs in tight locations. Some modern vehicles require special tools for accessing the transmission, so research your specific model before starting.

Quality tools make a difference in how smoothly this job goes. If you're unsure about your vehicle's specific requirements, our team at Blue Ridge Automotive can guide the correct fluid type and quantity for your particular make and model.

Follow These Safety Tips Before You Begin

Safety should always be your primary concern when working on any vehicle maintenance task. Follow these critical safety measures before beginning your transmission fluid change:

Ensure the vehicle is completely cool before starting. Transmission fluid can reach temperatures of 175°F or higher during normal operation and can cause severe burns if touched.

Park on a flat, level surface and engage the parking brake. For additional security, place wheel chocks behind the rear tires if working at the front of the vehicle, or in front of the front tires if working at the rear.

If using a jack, make sure to place jack stands securely under appropriate jacking points. Never rely solely on a hydraulic jack to support your vehicle while working underneath it.

Wear appropriate personal protective equipment, including:

- Safety glasses to protect your eyes from fluid splashes

- Gloves to protect your hands from hot components and chemicals

- Long sleeves to protect your arms from potential burns or cuts

Have a plan for the proper disposal of used transmission fluid. Used automotive fluids are hazardous waste and should never be poured down drains or onto the ground. Most auto parts stores and service centers, including our brake service center, accept used fluids for recycling.

Keep a fire extinguisher nearby as a precaution, and ensure your work area is well-ventilated to avoid breathing in fumes.

Perform a Fluid Change for Automatic Transmissions

Changing the fluid in an automatic transmission involves draining the old fluid, replacing the filter (if applicable), and refilling with fresh fluid. Follow these steps carefully:

Preparation and Draining

- Run the engine until it reaches normal operating temperature, which helps the fluid drain more completely.

- Turn off the engine, then raise and secure the vehicle using ramps or jack stands.

- Locate the transmission pan underneath your vehicle. It's typically rectangular or square-shaped with multiple bolts around its perimeter.

- Position your drain pan beneath the transmission pan.

- Loosen the pan bolts gradually in a cross pattern, leaving a few bolts slightly threaded on opposite sides.

- As you loosen the final bolts, the fluid will begin to seep out. Be careful; the pan may be full of fluid, so maintain pressure against it to control the flow.

- Carefully remove the transmission pan completely, allowing the remaining fluid to drain into your catch pan.

Filter Replacement and Cleaning

- Locate the transmission filter inside the transmission. It's usually attached to the valve body with bolts or clips.

- Remove the old filter and note its orientation for installing the new one.

- Clean the transmission pan thoroughly using solvent or brake cleaner, removing all metal particles and debris.

- Inspect the pan for damage, particularly the gasket sealing surface.

- Install the new filter according to the manufacturer's instructions, ensuring it's properly seated.

- Place the new gasket on the clean pan, using a small amount of gasket sealer at the corners if recommended by your vehicle manufacturer.

Reinstallation and Refilling

- Carefully position the pan with its new gasket against the transmission housing.

- Hand-thread all bolts first, then tighten in a cross pattern to the manufacturer's specifications using a torque wrench.

- Lower the vehicle if necessary to access the fill tube.

- Remove the transmission dipstick and insert a funnel.

- Add the new fluid gradually, checking the level frequently to avoid overfilling.

- Start the engine and let it run for a few minutes with the transmission in Park.

- Shift through all gears with your foot on the brake, then return to Park.

- Check the fluid level again, adding more if necessary.

The exact amount of fluid needed varies by vehicle, but typically ranges from 4 to 16 quarts for a complete change. Consult your owner's manual for the precise specification. Remember that overfilling can be just as harmful as underfilling.

Change Manual Transmission Fluid the Right Way

Manual transmission fluid changes are typically simpler than automatic ones, as they usually don't involve filter replacement. Here's how to perform this maintenance task:

Draining the Old Fluid

- Ensure the vehicle is completely cool before beginning.

- Raise and secure the vehicle using ramps or jack stands.

- Locate both the fill plug and drain plug on the transmission case. The fill plug is typically on the side of the transmission, while the drain plug is at the bottom.

- Remove the fill plug first. This is crucial because if you can't remove the fill plug, you won't be able to refill the transmission after draining.

- Once the fill plug is successfully removed, position your drain pan under the drain plug.

- Remove the drain plug and allow all fluid to drain completely.

- Inspect the drained fluid for metal particles, which could indicate transmission wear.

Refilling with Fresh Fluid

- Clean both the drain and fill plugs, and inspect their sealing washers.

- Replace the drain plug and tighten to the specified torque.

- Using a funnel with a flexible hose attachment, add the new fluid through the fill hole.

- Fill until fluid begins to seep out of the fill hole, which indicates the correct fluid level.

- Replace the fill plug and tighten to the specified torque.

- Lower the vehicle and test drive briefly.

- Check for leaks around both plugs.

Manual transmissions typically require between 2 and 4 quarts of fluid, depending on the vehicle. The exact type of fluid varies significantly between makes and models, with some requiring conventional gear oil while others need specialized synchronizer-friendly fluids.

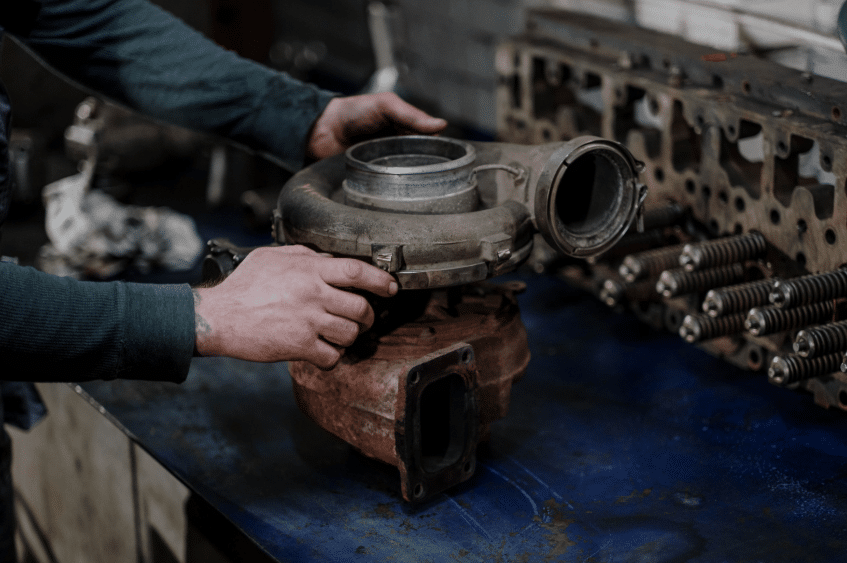

For high-performance vehicles or those with specialized components like those discussed in our turbocharger maintenance guide, specific transmission fluids may be required.

Adapt Your Approach Based on Vehicle Type

Different vehicles have unique transmission designs that may require special procedures during fluid changes. Here are some special considerations to keep in mind:

European Vehicles

Many European vehicles, particularly German brands like BMW, Mercedes-Benz, and Volkswagen, claim to have "lifetime" transmission fluid. However, most independent mechanics recommend changing this fluid every 60,000-80,000 miles. These vehicles often require specialized fluids and may need a professional-grade scanner to complete the procedure properly.

CVT Transmissions

Continuously Variable Transmissions (CVTs) are becoming increasingly common in newer vehicles. These transmissions have unique fluid requirements and often need special procedures for fluid changes. Using incorrect fluid in a CVT can cause catastrophic failure. Some CVTs also require a specific procedure to set the correct fluid level, which may involve checking the temperature with a scanner.

Hybrid Vehicles

Hybrid vehicles typically use specialized transmission fluid and may have unique draining and filling procedures. The high-voltage components in hybrid transmissions make these fluid changes particularly dangerous for DIYers without proper training. Consider consulting a professional for these vehicles.

4WD and AWD Vehicles

Four-wheel drive and all-wheel drive vehicles often have additional components like transfer cases and differentials that require their fluid changes. While performing your transmission fluid change, it's a good opportunity to check and service these components as well.

When in doubt about your specific vehicle's requirements, consult your owner's manual or reach out to a professional technician at Blue Ridge Automotive for guidance.

Solve Common Problems During Fluid Changes

Even with careful preparation, you might encounter some challenges during a DIY transmission fluid change. Here are solutions to common problems:

If the transmission pan bolts are stuck or stripped, try using penetrating oil and allowing it to soak before attempting removal again. For stripped bolts, a bolt extractor set may be necessary.

For overfilled transmissions, use a fluid transfer pump or a turkey baster to remove excess fluid until the level is correct. An overfilled transmission can cause foaming, pressure buildup, and seal damage.

If you notice metal particles or debris in your old fluid, this could indicate internal transmission wear. Small amounts of metal dust are normal, but large chunks or excessive debris warrant professional inspection before continuing to drive the vehicle.

Should you encounter leaks after completing the fluid change, first check that all plugs and bolts are tightened to specification. If leaking persists, the gasket may need replacement, or there could be an issue with the sealing surface.

For vehicles with no visible dipstick (common in newer models), the fluid level must be checked and filled through a special plug on the transmission case. This often requires the vehicle to be level and the fluid at a specific temperature, usually requiring a scanner to verify.

Know When to Bring in a Transmission Specialist

While changing transmission fluid is a manageable DIY project for many car enthusiasts, certain situations call for professional assistance. Consider consulting a professional mechanic at Blue Ridge Automotive if:

- Your vehicle has a sealed transmission advertised as "fill-for-life"

- You need to perform a complete transmission flush rather than a simple fluid change

- The manufacturer specifies a complex procedure requiring specialized equipment

- Your transmission is exhibiting symptoms like slipping, harsh shifts, or unusual noises

- You've discovered significant metal particles or debris in your old transmission fluid

- Your vehicle has a CVT or hybrid transmission system

- You're uncomfortable working with any aspect of the procedure

Professional transmission services often include comprehensive diagnostics that can identify potential issues before they become major problems. If you're uncertain about taking on this maintenance task yourself, check out our blog for more automotive maintenance tips or contact our service department for assistance.

Frequently Asked Questions

How often should I change my transmission fluid?

For automatic transmissions, most manufacturers recommend changing the fluid every 30,000 to 60,000 miles. Manual transmissions typically require fluid changes every 30,000 to 90,000 miles.

However, if you frequently tow heavy loads, drive in mountainous terrain, or experience stop-and-go traffic regularly, consider more frequent changes. Always check your owner's manual for the manufacturer's specific recommendations for your vehicle.

Is it true that changing transmission fluid in older vehicles can cause problems?

There's a common belief that changing transmission fluid in high-mileage vehicles can cause transmission failure. While it's true that in some cases an older transmission might begin slipping after a fluid change, this typically indicates the transmission was already failing.

The fresh fluid has different friction characteristics than the old, contaminated fluid, which can reveal pre-existing issues. If your vehicle has over 100,000 miles and has never had a transmission fluid change, consider consulting with a professional mechanic first.

What's the difference between a transmission fluid change and a transmission flush?

A transmission fluid change involves draining the fluid that sits in the pan (typically 40-50% of the total fluid) and replacing it with fresh fluid. A transmission flush uses specialized equipment to force out virtually all the old fluid from the transmission, including fluid in the torque converter and transmission cooler lines.

While a flush is more comprehensive, a simple fluid change is adequate for regular maintenance and can be performed at home, whereas a flush typically requires professional equipment.

How do I know if my transmission fluid needs changing if there's no dipstick?

Many modern vehicles have sealed transmissions without traditional dipsticks. For these vehicles, check the owner's manual for the recommended service interval. Some signs that indicate your fluid needs are changing include rough shifting, delayed engagement when putting the vehicle in gear, or unusual noises from the transmission.

These vehicles typically have a fill plug on the transmission case that requires special tools to access, and often need the fluid to be at a specific temperature when checking the level.

Can I mix different brands or types of transmission fluid?

It's not recommended to mix different brands or types of transmission fluid unless they specifically meet the same manufacturer specifications. Transmission fluids have unique friction modifiers and additives designed for specific transmissions.

Mixing incompatible fluids can cause shifting problems, accelerated wear, or even transmission failure. Always use the exact type of fluid specified in your owner's manual or by the transmission manufacturer.

Contact Blue Ridge Automotive for Trusted Transmission Service

Regular transmission fluid changes are a crucial aspect of vehicle maintenance that can significantly extend the life of your transmission and save you thousands in potential repair costs. While the process may seem intimidating at first, with the right tools, preparation, and guidance, many car owners can successfully perform this maintenance task themselves.

Remember to always use the correct fluid for your specific vehicle, follow safety precautions, and consult your owner's manual for manufacturer-specific instructions. If you encounter any complications or feel uncomfortable with the process, contact Blue Ridge Automotive for reliable help with your transmission service needs.

About Blue Ridge Automotive

Blue Ridge Automotive provides dependable vehicle maintenance and repair solutions built around precision, quality, and care. Our experienced team understands the technical details that matter most for reliable performance, including fluid services for all types of transmissions.

We take pride in offering hands-on expertise and trusted guidance for drivers looking to keep their vehicles running at their best. Contact us to schedule your next service or get answers to your transmission questions.

Have you ever heard a strange humming or grinding noise while driving that seems to get louder as you accelerate? That mysterious sound might be more than just an annoyance; it could be a warning sign of failing wheel bearings.

Wheel bearings are critical components that allow your wheels to spin freely while supporting the weight of your vehicle. When they begin to fail, they don't just create annoying sounds; they compromise your vehicle's safety and handling. At Blue Ridge Automotive, we see vehicles with wheel bearing issues every day.

In this comprehensive guide, we'll explore wheel bearing failure symptoms, decode the various sounds they make, and outline practical solutions to address these issues before they escalate into major repairs. Let's dive into everything you need to know about wheel bearing health and maintenance.

Discover How Wheel Bearings Keep You Safe on the Road

Wheel bearings are precision-engineered steel balls or rollers housed in a metal ring called a race. They're designed to reduce friction between the wheel hub and the axle, allowing your wheels to rotate smoothly while supporting the weight of your vehicle.

These seemingly simple components perform a complex and vital function in your vehicle's operation. Each wheel on your vehicle has its wheel bearing assembly. These bearings are packed with grease and sealed to keep contaminants out and lubricant in.

Modern wheel bearings are typically sealed units that aren't serviceable and must be replaced when they fail. However, some older vehicles may have bearings that can be repacked with grease during maintenance.

The importance of wheel bearings cannot be overstated. They not only enable smooth wheel rotation but also:

- Support the vehicle's weight while distributing loads evenly

- Allow minimal friction between moving parts, improving fuel efficiency

- Help maintain proper tire contact with the road for optimal handling

When wheel bearings begin to fail, your vehicle's safety and performance are directly affected. Excessive play in the bearings can lead to irregular tire wear, poor handling, and in extreme cases, complete wheel detachment, a catastrophic failure you certainly want to avoid. That's why understanding the signs of wheel bearing failure is crucial for every vehicle owner.

Catch These Early Signs Before Wheel Bearings Fail

Detecting wheel bearing problems early can save you from more extensive damage and costly repairs. Here are the key warning signs to watch for:

Unusual Noises

The most common symptom of a failing wheel bearing is noise. As bearings wear down, they produce the following distinctive sounds that often change with vehicle speed or when turning:

- Humming or Droning: A constant, low-pitched humming noise that increases with speed often indicates bearing wear.

- Growling or Rumbling: These deeper sounds typically occur when the bearing has significant damage.

- Clicking or Popping: These noises, especially during turns, suggest advanced bearing deterioration.

- Grinding: A harsh grinding sound usually means the bearing has little to no lubricant left, and metal-on-metal contact is occurring.

These noises may be more noticeable when accelerating, decelerating, or making turns. Many drivers report that the sound changes when turning in one direction versus the other, and this can help pinpoint which wheel bearing is failing.

Steering and Handling Issues

Failing wheel bearings don't just make noise; they affect how your vehicle handles. Look out for:

- Steering wheel vibration that increases with speed

- The vehicle is pulling to one side during normal driving

- Loose or "wandering" steering feel

- Increased steering effort, especially during turns

These wheel bearing failure symptoms can sometimes be confused with alignment or tire issues, but when combined with unusual noises, they strongly suggest wheel bearing problems. At Blue Ridge Automotive, our technicians can perform a thorough inspection to determine exactly what's causing these symptoms.

Visible Wear and Physical Symptoms

In addition to sounds and handling changes, physical signs can indicate wheel bearing issues:

- Uneven tire wear, particularly on the inner or outer edges

- Excessive heat around the wheel hub (which you might notice when washing your car)

- Visible play or movement in the wheel when jacked up and checked

- ABS warning light illumination (modern wheel bearings often house ABS sensors)

If you notice any of these symptoms, it's important to have your vehicle inspected promptly. Wheel bearing problems typically worsen over time, and addressing them early can prevent more serious damage to related components.

DIY Ways to Check for Wheel Bearing Trouble

While professional diagnosis is always recommended for wheel bearing issues, there are a few checks you can perform yourself to help determine if your suspicions are correct.

The first and simplest check is the "road test" method. Find a safe, straight road with minimal traffic and drive at a moderate speed (around 40 mph). Gently shift your vehicle's weight from side to side by slightly turning the steering wheel. If a wheel bearing is failing, the noise will often increase when you put weight on the affected side.

For a more hands-on approach, you can perform a basic wheel check if you have the tools and knowledge to safely jack up your vehicle:

- Properly secure your vehicle on jack stands (never rely solely on a jack)

- Grip the tire at the 12 and 6 o'clock positions and try to rock it

- Then grip at the 3 and 9 o'clock positions and repeat

Any noticeable movement or play could indicate a failing wheel bearing. However, some movement is normal in vehicles with certain suspension designs, so it's important to compare both sides of the vehicle.

Remember that wheel bearings aren't the only components that can cause similar symptoms. Worn suspension parts, damaged CV joints, or tire issues can produce comparable noises and handling problems.

That's why professional diagnosis from a trusted shop like Blue Ridge Automotive is invaluable; our experienced technicians can distinguish between these various issues and provide an accurate assessment.

Decode Wheel Bearing Noises and Their Severity

The sounds produced by failing wheel bearings can tell you a lot about the severity of the problem. Learning to interpret these noises can help you decide how urgently you need to address the issue.

Types of Wheel Bearing Noises

Different sounds typically correspond to different stages of bearing wear:

Early Stage Failure

- A subtle humming or drone that's most noticeable at highway speeds

- Noise that increases or decreases proportionally with vehicle speed

- Sound may disappear at certain speeds and reappear at others

Moderate Failure

- More pronounced growling or rumbling that's audible

- Noise that changes when turning or shifting weight in the vehicle

- Sound that worsens when cornering in one direction (typically louder when turning toward the affected side)

Advanced Failure

- Loud grinding or scraping that's impossible to ignore

- Constant noise regardless of speed or direction

- May be accompanied by vibration felt through the floor or steering wheel

The location of the noise can also help identify which bearing is failing. Front wheel bearing noise is often more noticeable when turning, while rear wheel bearing noise tends to be more constant. Noise from driver-side bearings is typically more audible to the driver, while passenger-side bearing noise might seem more distant.

It's important to note that wheel bearing noises can sometimes be confused with other issues. For example, tire noise from uneven wear patterns can mimic bearing sounds, and certain brake problems can produce similar grinding noises. This is why professional diagnosis from the skilled technicians at our brake services department can be invaluable in pinpointing the exact cause.

Know When It’s Time to Replace Wheel Bearings

Knowing when to replace wheel bearings is crucial for maintaining vehicle safety and preventing cascading damage to other components. Here's what you need to know about timing and necessity:

When Replacement Is Necessary

Unlike some vehicle components that can be serviced or repaired, modern wheel bearings are typically sealed units that must be replaced entirely when they fail. Here are some scenarios that necessitate replacement:

- When bearing noise becomes noticeable and consistent

- If there's any detectable play in the wheel when checked

- After significant water exposure (such as deep flooding)

- Following certain accidents or impacts that could damage the bearings

- As a preventive measure, when replacing other related components

- When an ABS sensor integrated with the bearing assembly fails

Typically, wheel bearings are designed to last 85,000-100,000 miles under normal driving conditions. However, factors like rough roads, frequent puddles or water crossings, and heavy loads can significantly reduce their lifespan.

The Replacement Process

Wheel bearing replacement is not typically a DIY job for most vehicle owners. The process requires specialized tools, precise torque specifications, and technical knowledge. Here's a simplified overview of what the replacement process involves:

- The vehicle is lifted and secured on a lift or jack stands

- Wheel and brake components are removed for access

- The hub assembly is detached (methods vary by vehicle design)

- The old bearing is pressed out, or the entire hub/bearing assembly is replaced

- New components are installed following the manufacturer's specifications

- Proper torque is applied to all fasteners

- The system is reassembled and tested

Many modern vehicles use hub assemblies that include the wheel bearing, hub, and sometimes the ABS sensor in a single unit. These "hub bearing assemblies" simplify the replacement process but can be more expensive than traditional bearings.

At Blue Ridge Automotive, our certified technicians have the tools and expertise to properly diagnose and replace wheel bearings on virtually any make and model. We ensure that all specifications are followed precisely, which is critical for bearing longevity and proper vehicle handling.

Pro Tips to Extend the Life of Your Wheel Bearings

While wheel bearings eventually wear out regardless of maintenance, their lifespan can be significantly extended through proper care and driving habits. Here are effective strategies to help prevent premature wheel bearing failure:

Driving Habits That Protect Your Bearings

How you drive and where you drive can have a substantial impact on wheel bearing life:

- Avoid hitting potholes and curbs when possible

- Reduce speed when driving on rough or uneven roads

- Avoid driving through deep water or puddles when you can

- Don't overload your vehicle beyond the manufacturer's specifications

- Use caution when towing to avoid excess strain on bearings

Maintenance Practices

Regular maintenance can help identify potential bearing issues before they become serious problems:

- Have your suspension checked regularly as part of routine maintenance

- Pay attention to tire wear patterns that might indicate bearing issues

- Address any unusual noises promptly

- Ensure proper wheel alignment and tire balance

On older vehicles with serviceable bearings, periodic repacking with fresh grease can extend bearing life. However, most modern vehicles use sealed bearings that cannot be serviced this way.

It's also worth noting that wheel bearings work in concert with other suspension components. Worn shocks and struts can place additional stress on wheel bearings, leading to premature failure. Maintaining your entire suspension system helps protect your bearings and other components.

Why Ignoring Wheel Bearing Issues Can Cost You More

Delaying wheel bearing replacement when problems arise can lead to significant consequences, both financially and safety-wise. Here's what can happen if wheel bearing issues are left unaddressed:

Safety Implications

Failing wheel bearings create the following serious safety hazards:

- Reduced vehicle control and unpredictable handling

- Compromised braking performance

- Risk of wheel seizure at high speeds

- In extreme cases, complete wheel detachment

These safety risks increase dramatically as bearing deterioration progresses. What starts as an annoying noise can quickly evolve into a dangerous driving condition.

Cascading Damage

When wheel bearings fail, they rarely fail alone. Expect these issues with wheel bearing failure:

- Damage to the wheel hub and spindle

- ABS sensor failure

- CV joint damage

- Potential damage to brake components

- Accelerated and uneven tire wear

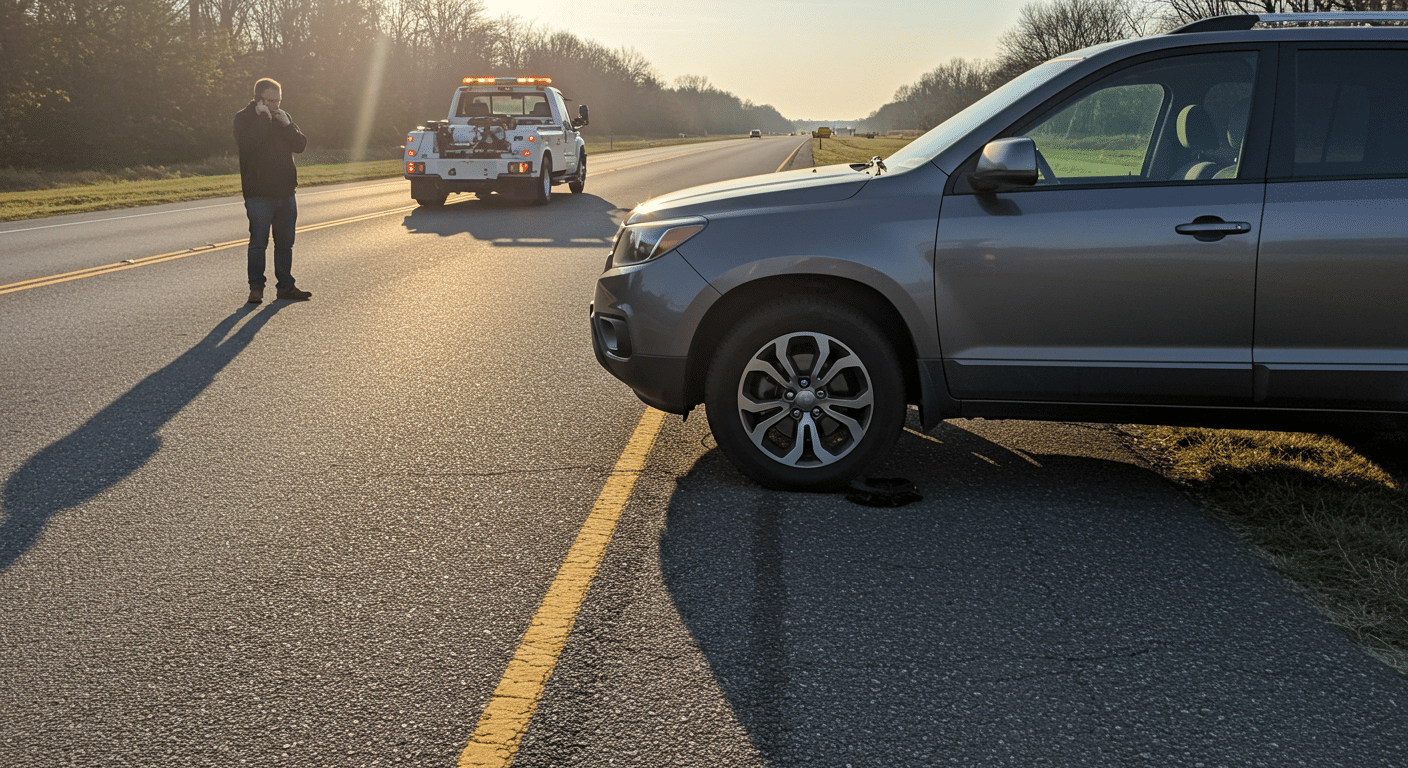

The cost of repairing this cascade of damage is typically much higher than addressing the bearing issue early. What might start as a $300-500 repair can easily balloon into repairs costing $1,000 or more when additional components become damaged.

Additionally, catastrophic bearing failure often leaves drivers stranded, necessitating a tow and creating inconvenience beyond just the repair costs. For busy professionals or families, this unexpected downtime can be particularly problematic.

At Blue Ridge Automotive, we've seen countless examples of minor bearing issues that evolved into major repairs because they were ignored. Our approach focuses on identifying these problems early during routine maintenance, potentially saving our clients significant money and hassle.

Frequently Asked Questions

How long can I drive with a bad wheel bearing?

While you might be able to drive for hundreds or even thousands of miles with early signs of wheel bearing wear, it's not recommended to drive any longer than necessary once you notice symptoms. A completely failed bearing can lock up without warning, causing you to lose control of your vehicle.

As soon as you identify wheel bearing noise or other symptoms, schedule a repair as soon as possible. Safety should always be your priority when dealing with critical components like wheel bearings.

Will a bad wheel bearing affect braking performance?

Yes, a failing wheel bearing can impact your braking performance. As the bearing deteriorates, it creates excessive play in the wheel assembly, which can cause uneven braking and increased stopping distances.

In vehicles with ABS, the wheel speed sensors are often integrated with the bearing assembly, so bearing failure can trigger ABS malfunctions or warning lights. Additionally, the heat generated by a failing bearing can potentially damage nearby brake components, further compromising your vehicle's stopping ability.

Can wheel bearings fail suddenly without warning?

While sudden, catastrophic wheel bearing failure without prior warning is rare, it can happen. Most wheel bearings deteriorate gradually, providing symptoms like noise and vibration for weeks or months before complete failure. However, severe impacts (like hitting a large pothole at high speed) can cause immediate damage that leads to rapid failure.

Water contamination from driving through deep puddles or floods can also wash away bearing lubricant, causing accelerated wear and potentially sudden failure. Regular vehicle inspections can help catch bearing issues before they reach this point.

Do I need to replace wheel bearings in pairs?

Unlike some components like struts or brake pads, wheel bearings don't necessarily need to be replaced in pairs. Each bearing wears independently based on road conditions, driving habits, and manufacturing variations.

However, if both front and rear bearings have similar mileage and one has failed, it's often wise to consider replacing both as a preventive maintenance measure. This approach can save you time and labor costs, as much of the expense in bearing replacement is in the labor rather than the parts themselves.

What's the average cost to replace wheel bearings?

Wheel bearing replacement costs vary significantly depending on your vehicle make and model, the type of bearing assembly, and your geographic location. On average, you can expect to pay between $250 and $500 per wheel for bearing replacement, including parts and labor.

Some luxury or specialized vehicles may cost more, sometimes exceeding $700 per wheel. Front wheel bearings often cost more to replace than rear ones due to their more complex design in many vehicles. Getting multiple quotes from reputable shops like ours can help ensure you're getting a fair price for quality work.

Contact Blue Ridge Automotive for Reliable Wheel Bearing Repair

Wheel bearings may be small components, but they play a massive role in your vehicle's safety and performance. Understanding the signs and sounds of wheel bearing failure empowers you to address issues before they escalate into dangerous and expensive problems.

From the distinctive humming and grinding noises to handling changes and physical symptoms, recognizing these warning signs early can save you significant money and prevent potential safety hazards on the road.

Remember that proper maintenance and careful driving habits can extend bearing life, but all bearings eventually require replacement. When that time comes, connect with Blue Ridge Automotive for trusted wheel bearing diagnostics and replacement services tailored to your specific vehicle.

About Blue Ridge Automotive

We provide trusted automotive care with a focus on safety, performance, and long-term value. Our team of certified technicians delivers reliable repair services, with deep experience in diagnosing and resolving wheel bearing issues across a wide range of vehicles.

Blue Ridge Automotive is committed to keeping your vehicle running smoothly with precision maintenance and repairs backed by years of hands-on experience. Contact us today to book an appointment or learn more about our services.

When automobiles first appeared on American roads in the early 1900s, few could imagine the profound transformation awaiting the auto repair industry. The history of auto mechanics is a story of adaptation, innovation, and technological revolution that parallels the evolution of the vehicles themselves.

From early blacksmith-run workshops to today's high-tech diagnostic centers, automotive repair has become a dynamic, skilled profession crucial to keeping America moving.

Early Beginnings: Blacksmiths and Bicycle Mechanics (1890s-1920s)

In the earliest days, cars were rare and unreliable, maintained by blacksmiths, bicycle repairmen, and machinery tinkerers. There was no formal auto repair industry yet. Blacksmith shops adapted to the needs of the motorized carriages, offering basic repairs using skills honed on wagons and horseshoes.

By 1910, as Ford's Model T made cars more accessible, dedicated repair shops emerged, often operating from converted stables or carriage houses. Mechanics relied heavily on intuition and improvised tools to fix mechanical issues. Service stations that sold fuel and offered maintenance created the foundation for the modern auto repair shop model.

Growth and Standardization (1930s-1950s)

Despite the economic strains of the Great Depression, car ownership remained widespread. The need for standardized repair methods grew. Manufacturers began publishing detailed service manuals, offering mechanics consistent guidance. Training programs emerged, formalizing what was once only learned through experience.

The 1940s, driven by the demands of WWII, produced a generation of skilled mechanics trained on military vehicles. After the war, many veterans opened repair shops, helping to fuel a boom in car maintenance services. The late 1940s and 1950s saw the rise of dealership service centers alongside independent garages, introducing multi-bay layouts and service advisors, structures still common today.

The Age of Specialization (1960s-1970s)

As cars became more complex, specialization became essential. The arrival of imported vehicles, emission control systems, and electronic ignitions demanded new knowledge. Dedicated import repair shops and specialists for systems like brake repairs and steering, and suspension repairs began to appear.

The establishment of the National Institute for Automotive Service Excellence (ASE) in 1972 helped standardize mechanic qualifications. Certification became important, ensuring that customers could identify well-trained technicians. This period laid the groundwork for a rapidly approaching technological shift.

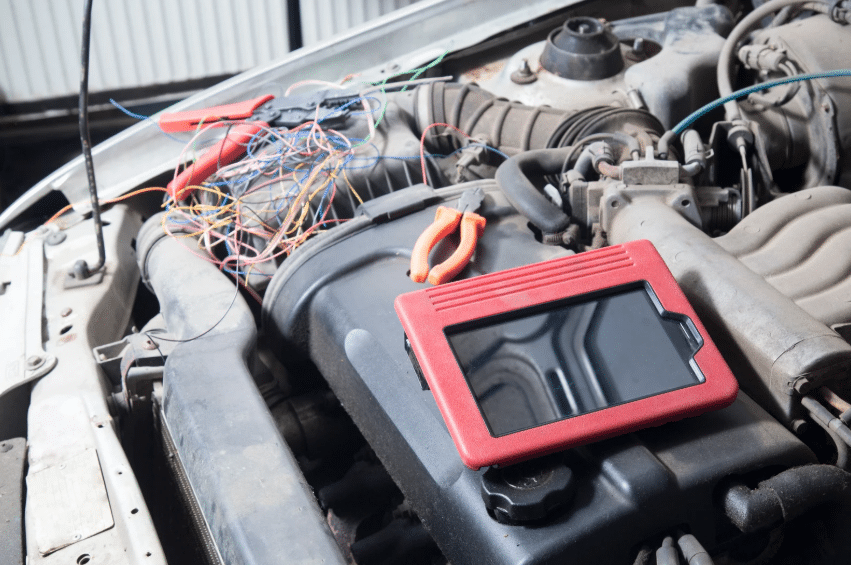

The Computer Revolution (1980s-1990s)

The introduction of onboard computers and early On-Board Diagnostics (OBD) systems in the 1980s marked a turning point. Technicians now needed to understand electronics, not just mechanics. Diagnostic scan tools became critical, allowing mechanics to read fault codes and access real-time performance data. Blue Ridge Automotive offers car diagnostic services to ensure accurate troubleshooting and repairs.

By 1996, OBD-II systems became standard, dramatically improving diagnostic precision and making troubleshooting more efficient. Training shifted to include electronics, sensors, and network systems. The divide between tech-savvy shops and those resistant to change grew wider.

During this time, essential services such as car engine repairs and transmission repairs demanded even greater technical expertise, as computerized components became more common in powertrains. This marked the start of a more structured automotive diagnostic process, streamlining how technicians approached problem-solving in modern vehicles.

The Digital Diagnostic Era (2000s-Present)

The 21st century has pushed digital diagnostics even further. Wireless diagnostic tools, cloud-based platforms, and remote access to manufacturer databases have become essential. Today's vehicles contain up to 100 interconnected computers managing everything from engine performance to driver assistance systems.

Technicians must now master digital tools, network protocols like CAN systems, and calibration procedures for advanced safety features. Electric and hybrid vehicles require certification in high-voltage systems, while remote diagnostics and predictive maintenance are changing customer expectations. Our coolant leak repair services ensure your engine stays protected under any driving conditions.

AI and machine learning are also starting to influence diagnostics, allowing systems to predict failures before they occur. This rise in AI automotive diagnostics is changing the landscape of preventive maintenance. Technicians are increasingly part-software specialists, part-mechanical experts, blending old-world craftsmanship with cutting-edge technology.

Meanwhile, services such as car exhaust repair and oil leak repair have evolved to incorporate precise digital assessments, ensuring efficient and accurate fixes that extend vehicle longevity.

Modern Diagnostic Practices: What Is Automotive Diagnostics?

What is automotive diagnostics? It’s the process of identifying, analyzing, and resolving mechanical and electronic issues in a vehicle using specialized tools and software. Today’s automotive diagnostic process involves interpreting real-time data from multiple systems to ensure vehicle performance, safety, and reliability.

These tools allow technicians to pinpoint issues more quickly than ever before, from minor sensor malfunctions to complex powertrain failures. This level of insight ensures faster, more effective repairs and reduces guesswork, ultimately saving time and money.

The Shift from Guesswork to Precision

One of the most remarkable changes in the auto industry has been the shift from trial-and-error repair methods to highly accurate diagnostics. In the past, mechanics often had to replace parts one at a time until the issue was resolved. This process was not only costly but also frustrating for vehicle owners.

Modern diagnostic tools eliminate much of this guesswork. With just a few scans, technicians can locate the root cause of a problem with near-pinpoint accuracy. This has led to more efficient repairs, reduced labor costs, and improved customer satisfaction.

Furthermore, diagnostic software is frequently updated with new data, ensuring compatibility with the latest vehicle models and technology. This makes it easier for technicians to stay ahead of emerging issues and service requirements.

The Human Element in a Digital Age

While technology has transformed the automotive repair industry, the role of the technician remains essential. Diagnostic tools provide information, but interpreting that data accurately still requires skill and experience. Technicians must combine digital data with mechanical insight to make the right repair decisions.

Customer communication has also evolved. With access to detailed diagnostic reports, shops can better explain issues and repair recommendations. This transparency builds trust and improves the overall service experience.

AI systems are designed to enhance, not replace, technicians. When used correctly, AI helps reduce diagnostic errors and improve repair timelines, giving technicians the ability to focus on critical tasks that require hands-on expertise.

Training the Next Generation of Technicians

As the industry advances, training programs must evolve alongside it. The next generation of technicians must be well-versed in both mechanical systems and digital diagnostics. Programs now include modules on software troubleshooting, electronic systems, and even cybersecurity as vehicles become more connected.

Continued education is vital. With every new model release, new diagnostic tools and processes are introduced. Technicians must engage in ongoing learning to stay current and remain competitive.

In addition, certifications like ASE remain critical benchmarks of quality. These certifications are increasingly incorporating diagnostic competency to reflect the growing importance of technology in auto repair.

The Broader Impact of Evolving Diagnostics

The advancements in diagnostics extend beyond individual repairs. Fleet operators now use advanced diagnostics to monitor entire fleets in real time. This allows for predictive maintenance scheduling, reduced downtime, and lower operational costs.

Consumers also benefit from enhanced diagnostics through features like remote monitoring and in-dash maintenance alerts. These tools empower car owners to take proactive steps before problems escalate, reducing long-term repair costs.

Environmental impact is another important consideration. Improved diagnostics reduce unnecessary part replacements and minimize waste. They also help maintain fuel efficiency and reduce emissions by keeping vehicles running at optimal performance.

Evolution of Auto Repair Shops and Customer Service

Alongside technological advancements, the structure of auto repair businesses has evolved. Franchise chains emerged, offering standardized services and branding. Mobile repair services gained popularity, offering customers convenience and flexibility.

Modern shops now integrate digital customer service features like online scheduling, CRM systems, and real-time updates. Environmental considerations have also reshaped shop practices, with stricter disposal regulations and greener products. Preventive maintenance has become a priority, aiming to reduce costly repairs through regular checkups like oil change services and car maintenance services.

Services have expanded beyond repairs to include customization, detailing, and advanced diagnostics. Additionally, the rise of tire repair services has become essential, as properly maintained tires are crucial for both performance and safety in today's high-tech vehicles.

The Future of Auto Repair

Looking ahead, augmented reality tools, expanded use of AI, remote repair capabilities, and a surge in electric vehicle service demands are set to transform the profession yet again. Autonomous vehicle systems will introduce entirely new maintenance categories, while sustainability will drive innovations in parts recycling and repair methods.

Auto technicians of the future will need to embrace continuous learning, adapt to new technologies, and prioritize digital literacy as much as mechanical skill. The same spirit of ingenuity that defined the early blacksmiths will continue to guide the industry through its next evolution.

Contact Blue Ridge Automotive to Keep Your Vehicle Running at Its Best

Ready to experience the benefits of modern auto care rooted in decades of trusted expertise? Reach out to Blue Ridge Automotive today. At Blue Ridge Automotive, our ASE-certified technicians combine hands-on craftsmanship with advanced diagnostic technology to keep your vehicle performing at its peak.

Whether you drive a classic car, a hybrid, or the latest electric model, we're here to provide the skilled service you deserve. Schedule your appointment now and drive with confidence knowing your car is in expert hands.

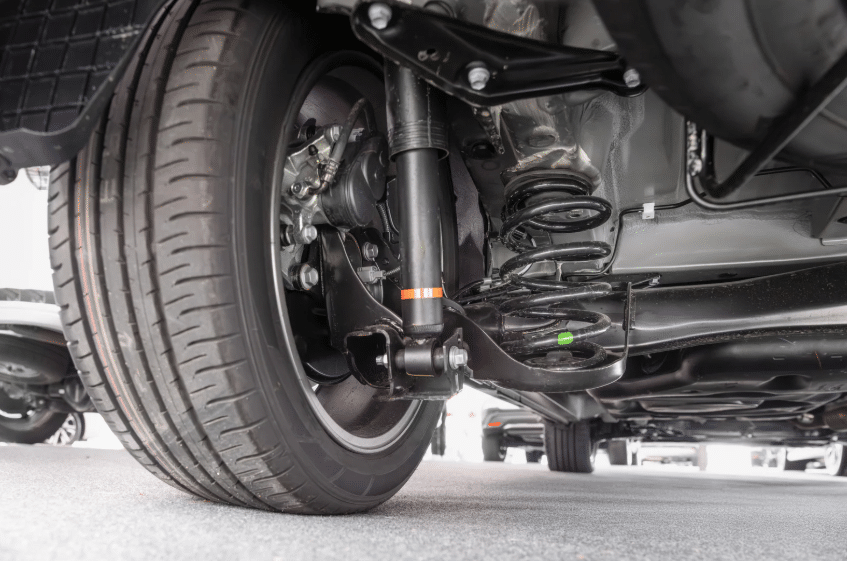

Your vehicle's suspension system is more than just a comfort feature; it's a crucial safety component that affects everything from handling to tire wear. Many drivers overlook regular suspension checks until they notice severe problems like uneven tire wear or difficulty controlling their vehicle. By then, the damage often extends beyond the suspension components themselves.

As modern vehicles have evolved with increasingly sophisticated systems, so too have the diagnostic approaches needed to maintain them properly. The transformation from manual inspections to digital diagnostics has revolutionized how mechanics identify suspension issues, making preventative maintenance more accessible than ever.

Understanding why suspension checks matter can save you thousands in unexpected repairs while extending the life of your tires and ensuring your safety on the road. Let's explore the critical relationship between suspension health and vehicle performance, and why regular checks should be part of your car maintenance service.

The Critical Role of Your Suspension System

Your vehicle's suspension system connects your car to its wheels, absorbing shocks from the road and maintaining optimal tire contact with the surface. Properly functioning suspension components can improve braking distances by up to 22% on uneven roads.

Key components like shock absorbers, struts, springs, control arms, and bushings stabilize your vehicle. Even on smooth roads, your suspension constantly adjusts to maintain control, leading to gradual wear. This wear intensifies in stop-and-go traffic and rough driving conditions.

How Suspension Issues Accelerate Tire Wear

When suspension parts fail, even weight distribution across tires disappears, causing uneven wear patterns. Here are two of the most common tire wear problems caused by suspension issues:

- Cupping and Scalloping: Worn shocks and struts cause tires to bounce and form dips across the tread.

- Misalignment: Worn control arms or tie rods create improper wheel angles, resulting in uneven tires.

A full set of premium tires can cost $600-$1,200. Proper suspension maintenance can prevent premature tire replacement and ensure consistent road grip, reducing accident risks. If tire issues have already started, timely tire repair can help extend their lifespan.

Steering and Suspension: A Vital Partnership

Steering and suspension systems work together to maintain stability and handling. A well-maintained steering system ensures precise control, while suspension evenly distributes weight for consistent traction. Neglecting one system often compromises the other, leading to increased tire wear and unstable vehicle behavior.

Power steering issues, worn bushings, and misalignment are common culprits. Regular inspections help identify these problems early, preserving both safety and performance.

Safety Implications of Neglected Suspension

Faulty suspension components dramatically increase stopping distances and reduce vehicle control during emergencies. Electronic stability systems like ABS depend on consistent tire contact with the road, which a healthy suspension system ensures.

Understeer, oversteer, and poor weight transfer during turns all point to suspension problems. In emergency maneuvers, worn suspension parts can mean the difference between maintaining control and losing it.

Warning Signs Your Suspension Needs Attention

If you notice any of these suspension issues, it's time to schedule a car diagnostic service to identify and fix the root cause before it worsens:

- Excessive bouncing after bumps

- Clunking, knocking, or squeaking sounds

- Uneven tire wear (cupping, feathering, edge wear)

- Vehicle pulling or wandering while driving straight

- Sagging or tilting when parked

The Professional Suspension Check Process

Professional checks catch problems early, allowing for less expensive repairs and improved safety. A thorough inspection involves several steps:

- Visual Examination: Checking for leaks, cracked bushings, and damaged parts.

- Hands-On Testing: Feeling for excessive play in ball joints, control arms, and tie rods.

- Advanced Diagnostics: Using digital tools to measure shock performance and detect subtle faults.

- Alignment Verification: Ensuring wheel angles meet manufacturer specifications.

- Road Testing: Evaluating real-world handling and listening for noises.

Suspension Maintenance and Its Impact on Tire Wear

A healthy suspension system keeps tires evenly engaged with the road, reducing irregular wear patterns. Misalignment, worn shocks, and damaged springs compromise tire life and overall handling. Routine inspections and timely suspension maintenance, like replacing shocks, adjusting alignment, and maintaining proper tire pressure, protect your investment in both tires and vehicle stability.

Preventative Maintenance: Scheduling and Cost Considerations

Experts recommend a suspension inspection every 12,000-15,000 miles, or every 8,000-10,000 miles for vehicles frequently exposed to rough conditions. Comprehensive inspections typically cost $80-$150, far less than a full suspension overhaul or emergency repairs.

Proactive maintenance extends component life, enhances resale value, and keeps your vehicle safe. In addition to suspension care, keeping up with essential services helps maintain your vehicle's overall health.

Scheduling an oil change service at regular intervals protects your engine, while addressing potential issues early through coolant leak repair ensures optimal cooling performance. Staying proactive with critical systems like brake repair also plays a major role in keeping your vehicle safe on the road.

DIY vs. Professional Suspension Checks

Basic DIY checks (like the bounce test and visual inspections) can spot obvious issues. However, many problems require professional tools and expertise to detect.

Professionals use lifts, shock testers, and alignment machines to identify hidden problems before they escalate. A hybrid approach, regular owner checks combined with scheduled professional suspension inspections, offers the best protection.

Contact Blue Ridge Automotive to Protect Your Vehicle and Stay Safe

Your suspension system affects far more than ride comfort; it’s crucial for tire longevity, vehicle stability, and your overall safety. Regular suspension checks help catch small issues early, saving money and preventing accidents.

Blue Ridge Automotive is Atlanta's trusted source for expert steering and suspension repair, complete diagnostics, and preventative maintenance. Our ASE-certified technicians use the latest diagnostic tools to keep your vehicle safe and performing at its best.

Don't wait for signs like bouncing, pulling, or uneven tire wear. Protect your investment and your safety by scheduling a professional suspension check. Contact Blue Ridge Automotive today to get started!

Frequently Asked Questions

How often should I have my suspension checked?

For most vehicles under normal driving conditions, schedule a professional suspension inspection every 12,000-15,000 miles or annually, whichever comes first.

If you frequently drive on rough roads, carry heavy loads, or notice any warning signs like unusual noises or uneven tire wear, increase this frequency to every 8,000-10,000 miles. Remember that preventative maintenance almost always costs less than reactive repairs after component failure.

What’s the connection between alignment and suspension?

While related, these are distinct aspects of your vehicle's handling system. Your suspension components physically connect your vehicle to its wheels and absorb road impacts, while alignment refers to the precise angles at which your wheels contact the road.

Suspension problems frequently cause alignment issues, but alignment problems don't necessarily indicate suspension damage. However, proper alignment depends on healthy suspension components, which is why comprehensive suspension checks typically include alignment verification.

Can a damaged suspension cause other problems?

Absolutely. Compromised suspension components create a cascade of problems throughout your vehicle. Beyond the obvious tire wear issues, suspension problems place additional strain on steering components, wheel bearings, and even your vehicle's frame.

The constant vibration from poor suspension can damage electronic components and accelerate wear on the engine, transmission mounts, and even your car’s exhaust system. Additionally, the extra stress placed on remaining functional suspension parts and connected systems, like the transmission, accelerates their deterioration, creating a rapidly expanding cycle of damage.

What causes premature suspension wear?

Several factors accelerate suspension wear. Frequent driving on roads with potholes or uneven surfaces creates additional stress on components. Stop-and-go traffic conditions force your suspension to handle repeated weight transfers that accelerate wear.

Overloading your vehicle beyond manufacturer-recommended weight limits places excessive strain on springs, struts, and associated components. Environmental factors like road salt and extreme temperatures can accelerate corrosion and deterioration of rubber bushings. Regular maintenance can help mitigate these factors.

Are aftermarket suspension parts reliable?

Quality varies significantly across aftermarket brands. Premium aftermarket manufacturers often produce components that match or exceed OEM specifications, sometimes offering improved designs or materials that outperform original equipment. However, budget aftermarket parts frequently use inferior materials that deteriorate faster, leading to issues like premature car engine repair, oil leak repair, or even problems with your car’s AC system.

For optimal results, research specific brands and consult with experienced technicians who can recommend reliable aftermarket alternatives when appropriate. Remember that saving money on inferior components typically costs more in the long run through increased frequency of replacement and unexpected repairs.

Your vehicle's transmission is a complex system that often goes unnoticed until problems arise. Regular transmission maintenance isn't just about avoiding costly repairs; it's about extending the overall lifespan of your vehicle. The transmission serves as the crucial link between your engine and wheels, managing power distribution to keep your vehicle running smoothly.

When neglected, transmission issues can cascade into major mechanical failures that may render your vehicle unusable. The good news? With consistent maintenance and early intervention, most serious transmission problems can be prevented entirely.

By understanding how proper transmission care impacts your car's longevity, you can make informed decisions that save you thousands of dollars and countless headaches down the road. Today, we'll explore essential maintenance practices that keep your transmission healthy, warning signs that demand attention, and expert tips for maximizing your vehicle's lifespan through proper transmission care.

Understanding Your Vehicle's Transmission System

The automotive industry has seen remarkable advancements in transmission technology over the decades. The evolution of car diagnostic services has transformed from basic mechanical observations to sophisticated computer-based analyses that can detect problems before they become serious issues.

These advancements allow for more precise maintenance and earlier intervention when problems begin to develop. Understanding your specific transmission type helps you recognize normal operation versus concerning symptoms. This knowledge forms the foundation for proper maintenance and timely repairs that extend your vehicle's useful life.

At its core, your transmission:

- Converts the engine's power into torque that propels your vehicle forward

- Consists of gears, hydraulic systems, electronic components, and specialized fluid

- Requires all components to work together seamlessly for proper function

Adapting Maintenance for Different Transmission Types

Each transmission type, whether automatic, manual, or CVT, has unique maintenance requirements and common failure points. Understanding these differences helps you provide appropriate care for your specific vehicle configuration.

Automatic Transmissions:

- Most common in North American vehicles.

- Rely on hydraulic systems and require regular fluid changes.

- Fluid degrades faster due to heat during operation.

- May need occasional band adjustments (though many newer models self-adjust).

Manual Transmissions:

- Require less frequent maintenance than automatics.

- Main needs include clutch adjustments, clutch replacements, and gear oil changes.

- Simpler design often leads to a longer lifespan when properly maintained.

- Clutch replacement is a major service that manual drivers should expect.

CVT (Continuously Variable Transmissions):

- Use a belt and pulley system instead of traditional gears.